Wendell Global Interlinings Group is pleased to introduce our company to the TEGRA Family

115 Year Old Company

Family Owned Since Inception

No Debt – No Loans – No Factors

Over 1200 Employees Strong

What makes us different

We Have a Passion For Our Product

Most importantly We understand our customer

We provide solutions to capture the customer’s needs of cost, quality, inventory and “just in time” delivery, and balance those requirements to provide synergistic results to our partners.

Meet our friends…

Fruit of the loom

Gildan

Cintas

Aramark

Dickies (a vf company)

Haggar

Jc-penney-arizona

Unifirst

Hanes

Levi

Kontoor Brands –

Wrangler and

Lee Brands

VF-Workwear & Workrite

Joe’s jeans

Hollister-a&f

Paige jeans

Eddie bauer

Pepe jeans

Infinity uniforms- riverside MFG.

Liverpool-mexico

Centric Brands

Target Brands

Private Label

Land and sea

Dress barn

Walmart

Tommy hilfiger

United jeans

Gap-banana republic

Hudson jeans

Loveable bra

Li-fung

Lobo-mexico

J-Brand Jeans

L.L Bean

Lanier Clothes

US Military Programs

Propper International

501 Tactical

New Holland (a Tegra Company)

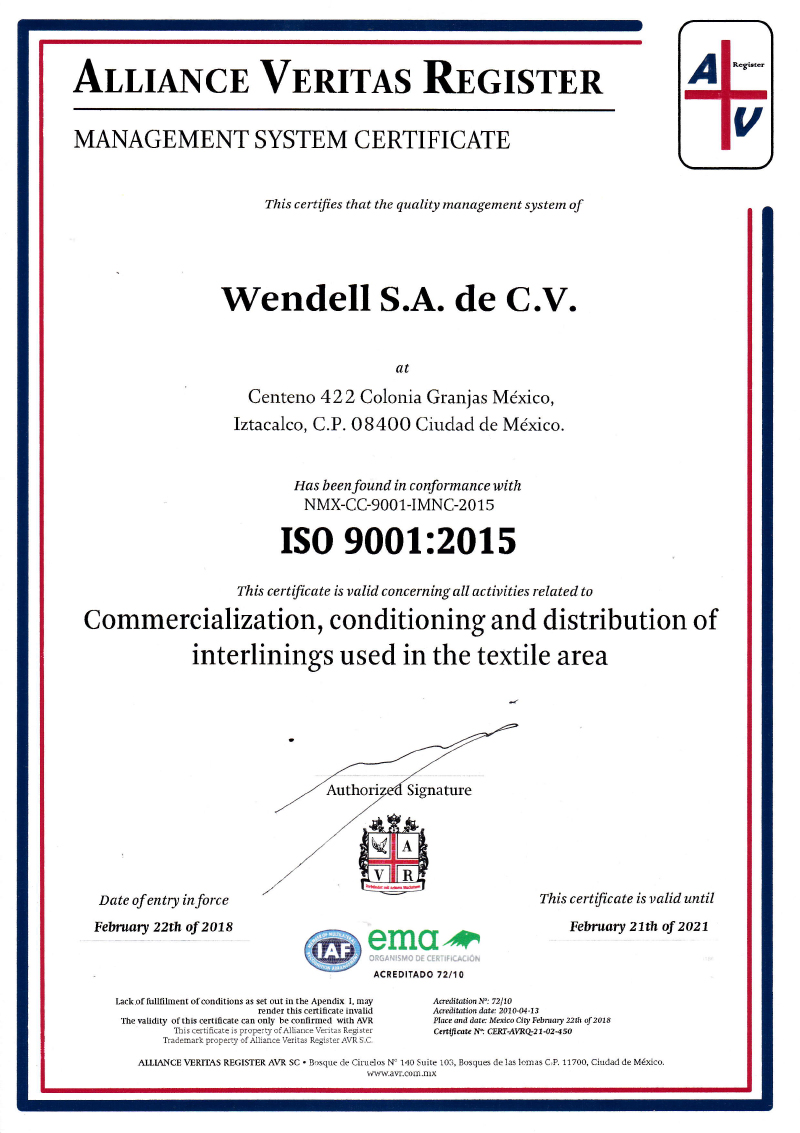

qs-9001-2015 certification

0eko-tex certification

continuous improvement efforts

less than .0001% defect rates

continuous inspection methods

certification of raw material

green footprint initiatives

Usa

Production – Baltimore, Maryland

City of Commerce, Los Angeles, CA

Central America (Free zone locations)

San Pedro Sula, Honduras

Santiago, Dominican Republic

Guatemala City, Guatemala

San Salvador, El Salvador

Managua, Nicaragua

Port au Prince, Haiti

Mexico

Mexico City-Corporate Office, Warehouse and Technical Support

Torreon-Matamoros-Gomez Palacio

Tehuacan

Teziutlan

Monterrey

Puebla-Iguala

Guadalajara

Merida

Augascalientes

Pachuca

South America

Colombia

Medillin-South America International Sales Office

Rio-Negro Free Zone-Warehouse

Medellin-Local Warehouse

Cali

Bogota

Pereira

Medellin

Ecuador

Guayaquil

Quito

Asia

Hong Kong Office-Sales and Logistic

Tai-Zhou City-Manfacturing

Bangladesh

Dhaka

SouthEast and Pacific Rim

Staff of 4 Export Managers

6 Container per week capacity

(1,200,000 YARDS OF 60” Rolls per month)

Inventory stock levels in excess of

(2,000,000 yards on any given day)

Daily shipment to Shanghai Port via our customer’s brokers (for those who prefer to import from China), as well as Air shipments

Daily shipments made to all areas of China within a 48 hour period, as well as Professional and comprehensive Technical Support 24 hours a day

(as well as all support for all locations)

Weekly shipments are also made to (and available to):

Bangladesh, Vietnam, Sri Lanka, Kenya (Africa)

Inventory stock programs are available in all countries, with a projection bounded program

Comprehensive Laboratory Test Reports are available upon request and can be delivered in 48 hours to any location

(after we receive customer’s fabric)

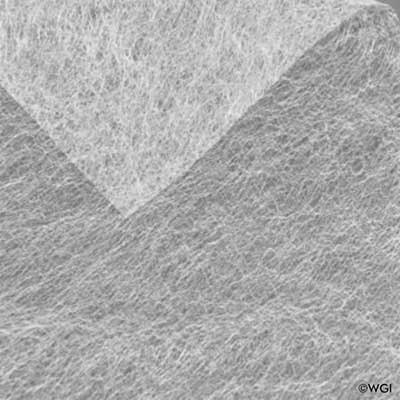

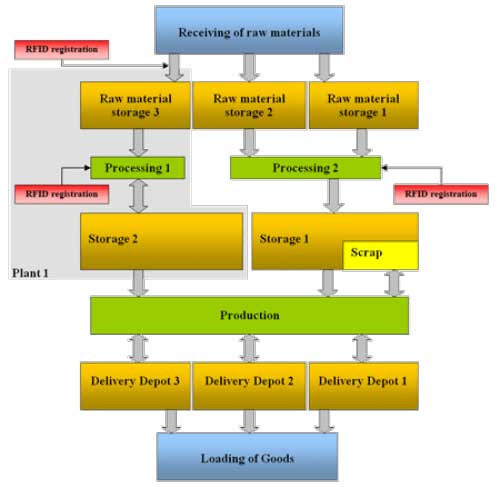

Manufacturing

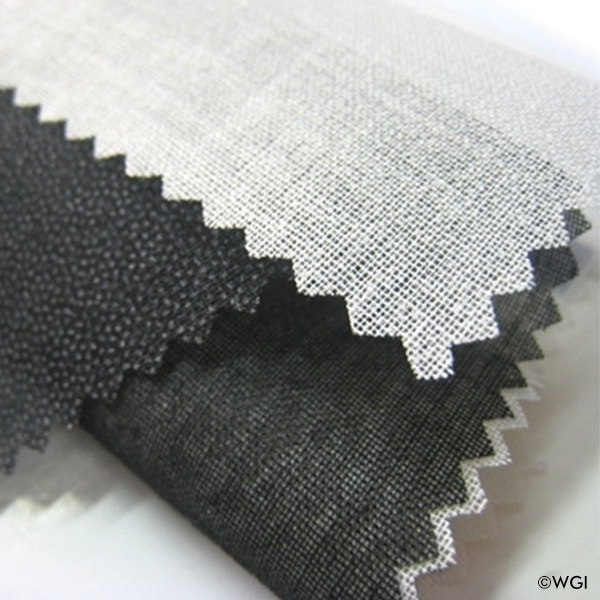

Fusible Interlinings

Wovens

Knitted

Nonwovens

Film & Web Extrusion

Logistics

30 Locations Worldwide

Company Owned Locations

Stock at Point of Sale

Delivery Times Within 24 Hours

Research & development

Continuous Process of Research & Development Inspires…

Enhanced Quality

Reduced Cost Models

Special Use Applications

Team Concept – From Idea to Application

Point of sale converter

Die Cutting

Roll Cutting

Bias Cutting

Slotting – Fuse & Fold

On site technical support

On Site Country Support

Over 120 Years Experience in Product Applications

Experience Working in Customer’s Factory & Sew Lines for Fusing Applications

Testing and Laboratory

We provide laboratory testing in 72 hours which is performed during pre-production when considering a new fabric or change in interlining

What you will learn

We test bond and adhesion levels in N (Newtons) levels before and after wash

We water wash, dry clean , acid wash, stone wash and golf ball wash

We check for appearance on the face and back of fabric

We check for shrinkage

We sew “mock-ups” to confirm sewing process and alignment with unobstructed sew lines

We provide our statement of opinion and recommendation

Why Test?

Testing is your guarantee from Wendell that if the production factory follows our manufacturer’s specification that the product will preform as confirmed by our test report

Wendell provides in-factory on site testing of all types of fusing presses

We test machine pressure and temperature

We test machine time

We check machine operation and maintenance

We clean machine belts to remove residual resins

We verify shrinkage and bond levels

We inspect for fabric and interlining compatibility

Support Managers

monica@wendellservices.com

michael@wendellservices.com

Honduras

technical support • jessica@wendellservices.com

technical support • pamela@wendellservices.com

engineering support • alexander@wendellservices.com

Nicaragua

technical support • cid@wendellservices.com

El salvador

technical support • noe@wendellservices.com

Guatemala

technical support • juan@wendellservices.com

Colombia & Ecuador

technical support • diana@wendellservices.com

Haiti

technical support • haiti@wendellservices.com

Dominican republic

technical support • arsenio@wendellservices.com

United states

customer support • dave@wendellservices.com

Los Angeles, CA

customer support • tom@wendellservices.com

Western hemisphere quality & iso manager

Jose Luis Chavarria • controldecalidad@wendellservices.com

Global product development manager

Michael Baguer • michael@wendellservices.com

Accounts receivable

Export and compliance

Mexico

Technical support manager

Hugo Sanchez • hugo@wendellservices.com

Support teams and warehouses

Corporate Office – Mexico City

Torreon • Monterrey • Guadalajara • Pubela • Veracruz • Queretaro • Pachuca • Augascalientes • Tehuacan • Teziutlan

Asia factory

Exports & production

Customer service

2018- Purchased

1 New Coating Machine

New Dry Dot Technology

$535,000 Self Funded

2018 – China Environmental Initiative

Water Coolers

Dye Stuff Cleaners

Scrubbers

Move to Food Based Chemicals and Pre Dyed Fibers

Funds by China Accord for Guaranteed Employee Based Agreement

2017

Opened Expanded Honduras Facility

Machinery and Operations

$180,000 Self Funded

2016/2017

Opened Colombia Operation and South America

Established Offices, Warehouse, Sales, Import and Export in Colombia

Headquarters Office in Medellin

Locations in Bogota and Pereira

$300,000 Self Funded

2016/2017

Opened Haiti Warehouse in Port Au Prince

$40,000 Self Funded

Joint Venture Initiative with Large Customer

2014/2015/2016

China Factory

Purchased 120 Toyota Looms

Invested in Clean Finishing Operations

Purchased One German Nonwoven Production Line

Total Investment $850,000

Investment From Owners

Future Investment Plan

2019-2021

Continued Clean Requirements For China Production and Reduced Energy Plan

2019

High Speed Cutting Machines in Mexico

Feasibility Study for Relocation of Coating and ‘Hard” Production in USA for Military-Berry Compliance

2019/2020

Expansions to Equador-Peru

Wendell Support At 2 Levels

Factory Mill Initiatives

2017 – Changed Boilers From Coal And Wood To Natural Gas That Feed Heavy Cans For Drying And Cooling

2018 – Reduced Water Usage And All Water Enters New China Treatment Facility

80% Of Our Polyester Fibers Are Recycled

Implemented A Tree Planting Project Around The Factory For Cleaner Air And Fresher Environment

Warehouse, Sales & Distribution Facilities Are Doing Their Part

Installed Solar Lamps In Outside Areas

Using Water Tanks to Reuse Rain Water For Bathrooms And Cleaning

Recycling Plastic And Waste In All Locations

Following Ministry Of Environment Recommendations In Each Country

Clearing & Cleaning Ceilings Regularly To Reduce Power Usage

Various Locations Beginning Weekly Educational Group Discussions To Teach Ways To Handle Plastic And Instill A Culture Of Recycling

Our Team Cares

Every Christmas the Wendell Family around the world takes 2 days off of work to paint orphanages , deliver gifts to hospitals and build extra rooms, bathrooms and rewire orphanages

The Wendell Mexico team has a adopted a Mexico City Orphanage and provides monthly emotional support and our engineering teams are deployed to work monthly to handle routine repairs and maintenance

We routinely offer gifts and toys to orphans in Santa Cruz delivered by Wendell Team Members

The Wendell Family engages in “Give a Bike to Children ” Campaign provide millions of free bikes yearly to children in poverty

Our list of giving back is as big as our hearts

Geotextiles

Automotive

Laminations

Filters

Partagas

Swisher

Montecristo

Aura

Punch

Romeo-Julieta

Cohiba

Macanudo

Upmann

Davidoff

What happens if we don’t develop new technologies to incorporate in our garments?

Un-Captured Quality Gains In Products That Can Increase Your Quality Standards

Loss Of Support To Engineer Platform

Increased Cost

Loss Of Cutting Edge Advantages

Ideas for Collaboration and Successful development

Place A Team Leader To Review The Product Benefits And Cost

Follow Through With The Work, Communicate With The Supplier And Trust The Supplier Expertise

Set And Meet Deadlines

Cost isn’t everything, There Are High Value Benefits Not Seen In A Price Tag

Pick Your Partners Well, Your Brand Should never be compromised

Transparency from Both Sides increases efficiency

Such as communication on Development, access to Factories management, Engineers and Quality

Why us?

We are passionate

We are committed

We are trusted

We have over 120 years of reputation and history

What we bring to the party

Geography

We are where you are

Quality

We offer continuous improvement-ISO Certified

Lean

Inventory support-just in time replenishment

Service

Committed long term team members

Innovation

We are driven by product development

Financial health

No debt-no constraints

Price

Highest value-driven by efficiencies and uniqueness

Capacity

Managed and consistent investment directives

Flexibility

Transparency and risk management

The extras

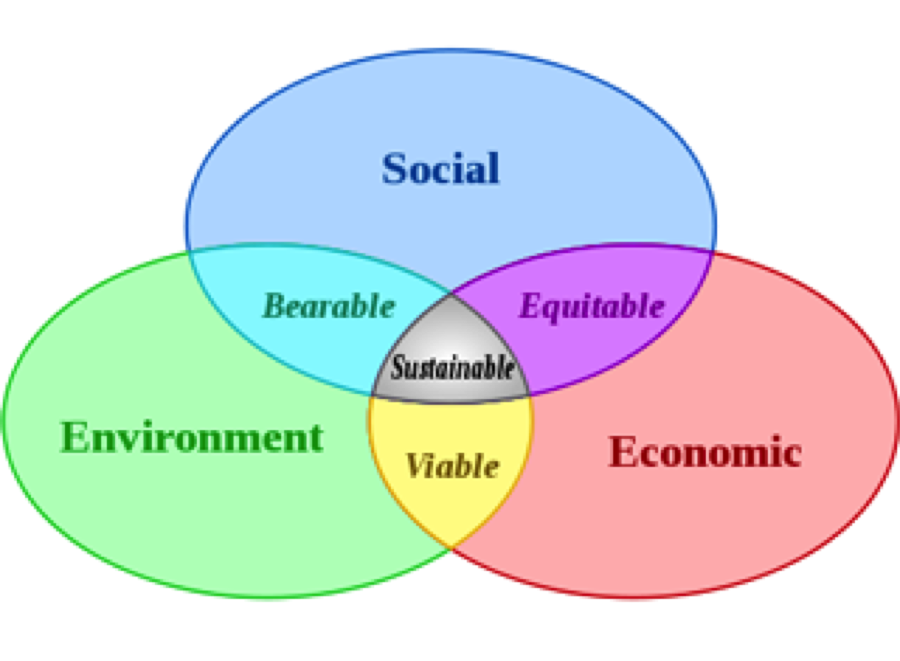

Socially Responsible Company

Collaboration

Technology Transfer

Shared Visions

SPECIAL EDITION

Focus On Honduras & Nicaragua

Fast Response Time

Processing

Die Cut

Roll Cut

Inspection

Perforation

Enhanced Technical Support

Import and Export Service

Warehousing

Over 50 Different Styles

30,000 Square Feet

Weekly Trucks Deliver To All Central America Locations

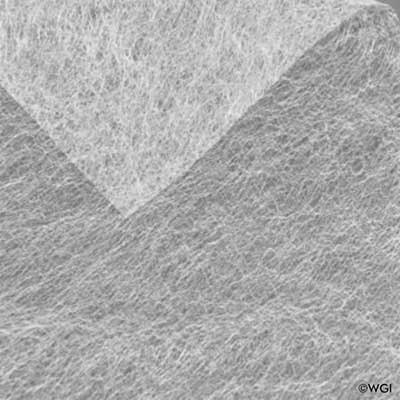

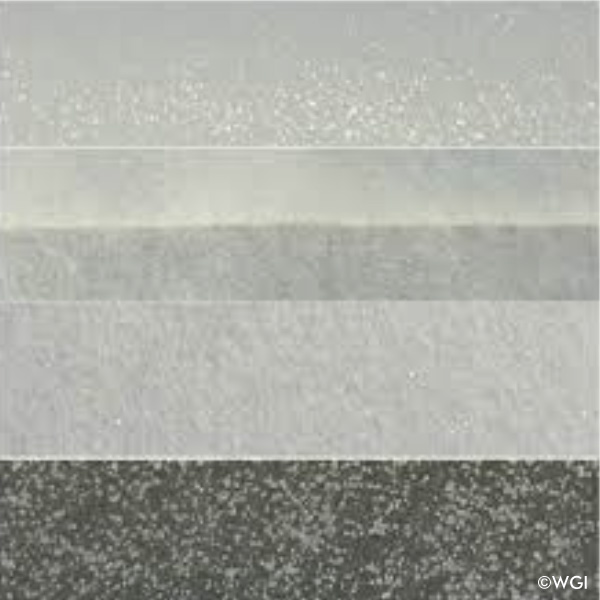

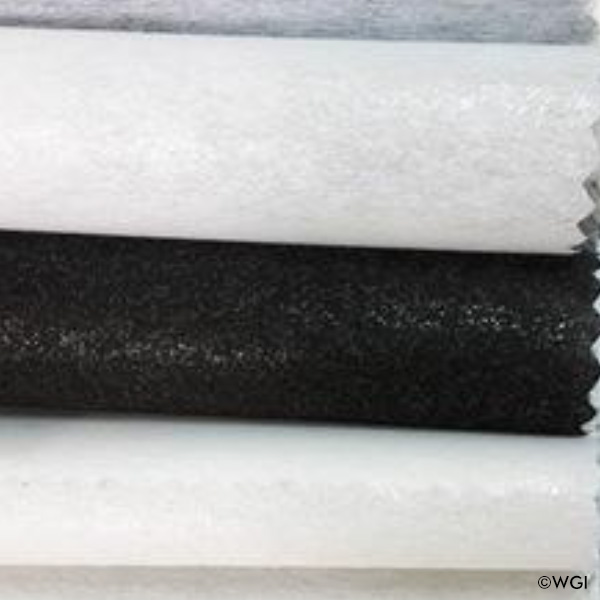

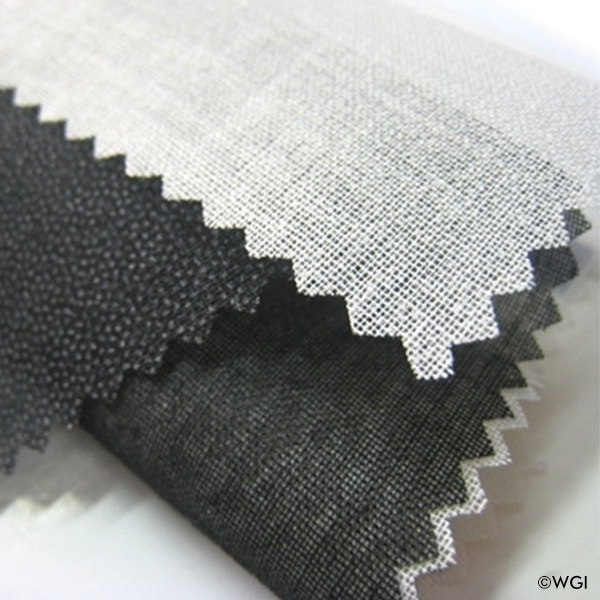

Nonwovens

100% POLYESTER & 100% RAYON & POLYESTER-RAYON BLENDS

10 Grams to 220 Gram Weights

Soft and Firm Hands – Various Binder – Fiber Ratios

Multi – Directional – Cross Lapped and Uni – Directional Web Orientation

Up to 1 to 1 Cross (CD) and Machine Direction (MD) Strength

Strength, Flexible, and Elastic Recovery

Formaldehyde Free

Highly Consistent Web Formation

High-Level of Tensile Strength and Elongation Rate

Available High Loft, Density, and Thick Characteristic

Cutaway and Tearaway Embroidery Backings

Composites – Filtration – Medical

Water Repellant – Flame Retardant

Colors – Dyed and Printed – Industrial Wipes

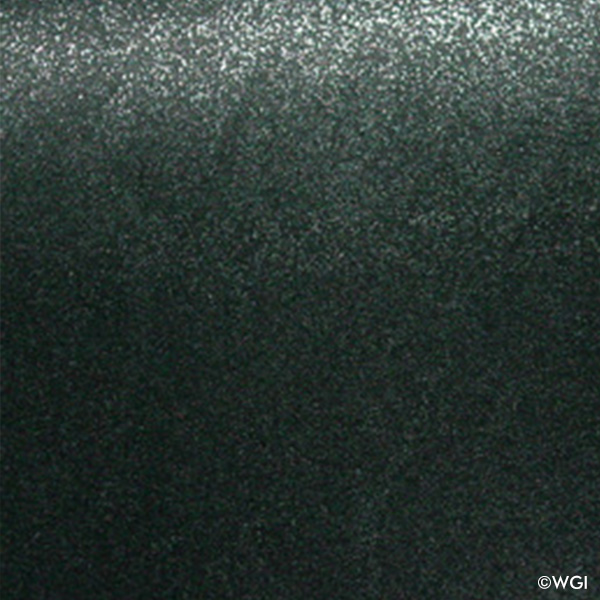

VARIOUS FIBER BLENDS

100% Polyester & 100% Nylon & Polyester – Nylon Blends

Weights from 10 GSM to 150 GSM

3 Double Width High Speed Line Capacity

2015 – Germans Highest Technology

Unidirectional and Cross Lapped

Precision Blending and Opening

In-Line Computer Controlled Production

High Tensile Strength in Machine and Cross Direction

Excellent Web Consistency

Soft to Firm Hands

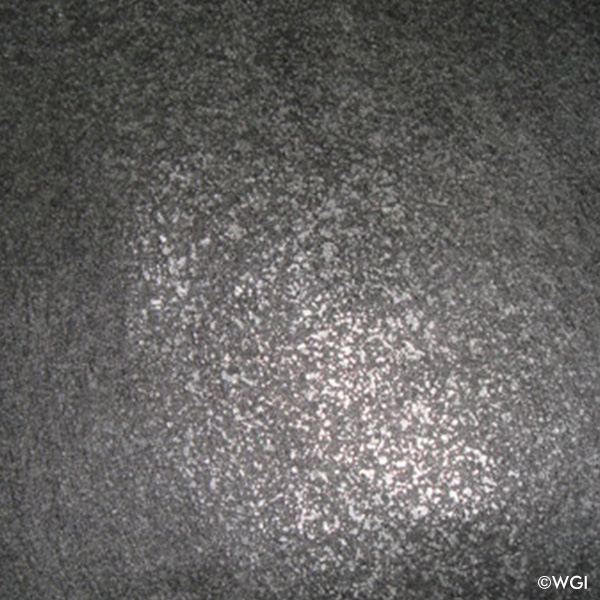

No-Pill Quality Surface Appearance

In-Line Finishing

Flame-Retardant Fibers

Water-Proof & Good Absorbability – Breath Free

Anti-Static & Drapable

Colors

Super White Color – Dark Black and Charcoal Blends

Polyester and Polypropylene

1” to 200” width & 40 GPM to 500 GSM.

1-side and 2-side calendared

Infrared bonded finish

Pliable • Softness • Moldable • Durable • Flame-Retardant • Liquid Repellent • UV Treated • Absorbency Resilience • Stretch • Washable

Filtering • Bacterial Barrier Sterility • Ecologically Friendly • Composite • Structures • Coated • Fusible-Coated

APPLICATIONS

Automotive Fabrics: Head liners • carpets • door trim • parcel shelves • molded components using low melt fibers • insulation felts • Carpet Pads • Safety Matts

Home textiles: Carpets • wall coverings • decor felts • wipes • blankets • Hobby and Crafts • Quilting

Synthetic leather: Shoe • automotive and upholstery industry • luggage • bags

Clothing and furniture: Shoulder pads • waddings • mattresses

Filters for gases and liquids

Polishing felts and Industrial Wipes

Abrasive felts • Mineral fiber felts for insulation • Liquid Filter Media • Oil Absorbent Pads

Laminations and Coating substrates

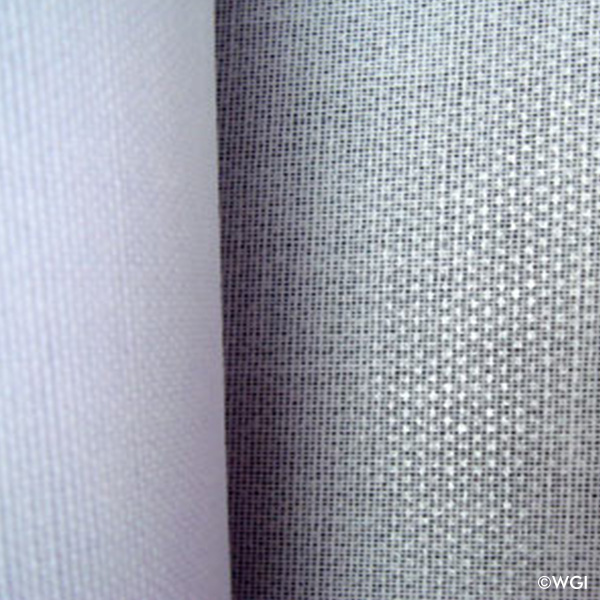

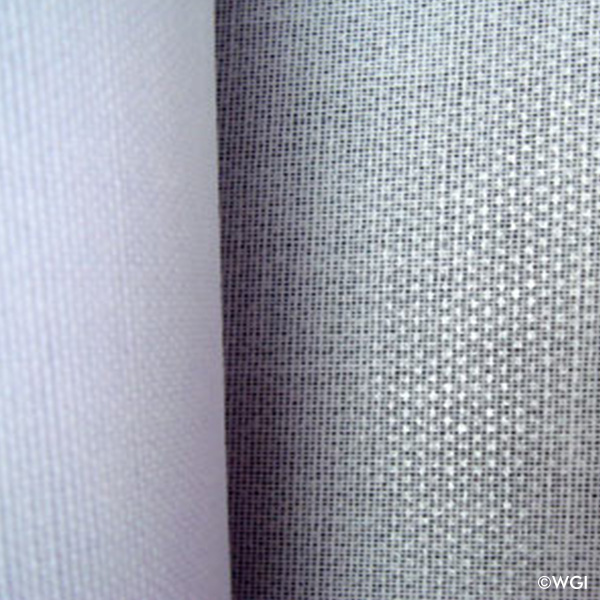

Weaving

COTTON & POLYESTER – COTTON – TC – BLENDS

FINISHING AND BLEACHING

ORGANIC COTTON

SHIRT INTERLININGS

CAP & WAISTBAND

High Density Polyethylene

24-26-28-30-32 Mesh Dot Coatings

Light To Heavy Weights 80 GSM-120GSM

Soft – Firm Finishes

< 2% Shrinkage

90CM – 152CM Wide

Brushed Raised Finishes

White Shading Controlled – Pure White

Yarn-dyed Black and DTM

Typical Counts

54×62 • 62×62 • 58×50 • 56×56 • 49×50 • 60×58 • 50×50 • 62×62 • 68×68 • 96×72 • 110×76 • 68×62 • 49×42 • 78×78 • 50×40

Yarns

12S • 20S • 21S • 28S • 30S • 32S • 40S • 45S

Blend Options

100% Cotton • 100% Polyester

90% Polyester – 10% Cotton

80% Polyester – 20% Cotton

70% Polyester – 30% Cotton

50% Polyester – 50% Cotton

30% Polyester – 70% Cotton

20% Polyester – 80% Cotton

POLYESTER WEAVING

WATER JET LOOMS

100% Polyester Interlining

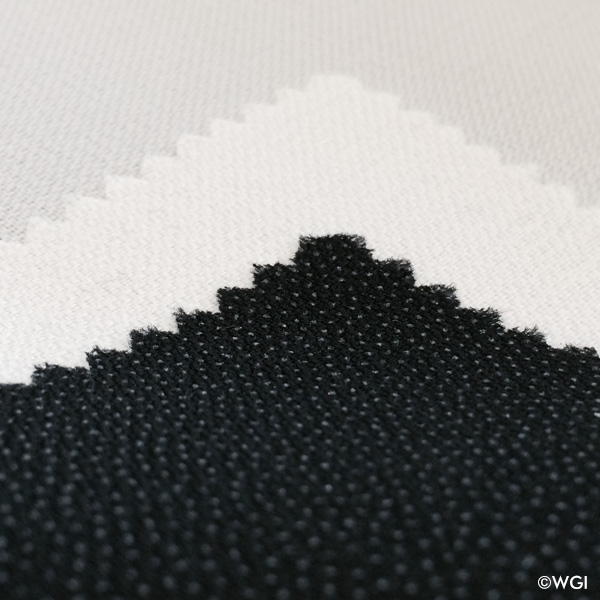

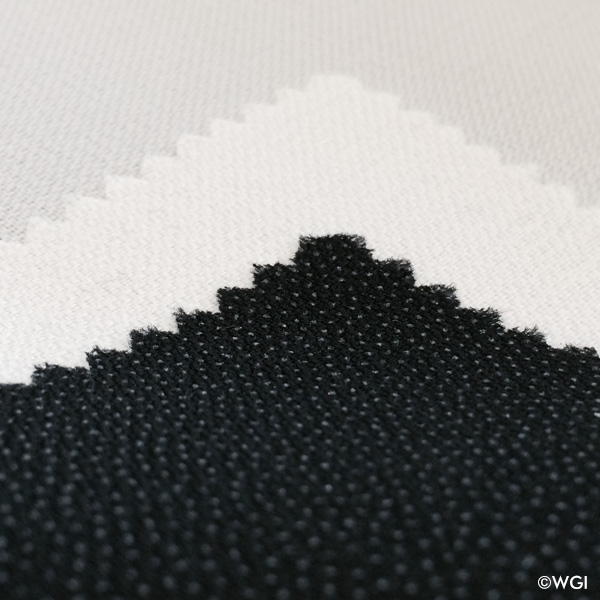

Double Dot Coated – Polyamide – Polyester – Blends

Specialized Coatings

Low Temperature Fuse & High Temperature Enzyme Wash

SPECIFICATIONS

20D*20D • 30D*30D • 50D*50D

75D*75D • 75D*100D • 75D*150D

20GSM • 30GSM • 40GSM • 50GSM • 60GSM

65GSM • 70GSM • 80GSM • 90GSM • 100GSM

Colors–Yarn Dyed

Plain Weave • Twill Weave • Satin Weave

Bi-Stretch

Two-Way Spandex Stretch • Four-Way Stretch • Lycra-Elastic Composite

Knitting Division

FUSIBLE CIRCULAR KNITS

100% POLYESTER

20D • 30D • 40D • 50D • 70D • 100D

25 GSM – 100GSM

Double Dot Coating

Polyamide & Polyester & Blends

6 GSM – 25 GSM

Enzyme Wash

RASCHEL WEFTS

100% POLYESTER & POLYESTER & VISCOSE BLENDS

80 GSM – 150GSM

Napped

Double Dot Coating

Polyamide & Polyester & Blends

6 GSM – 35 GSM

TEXTURED WEFT INSERTION KNITTING

100% POLYESTER

30 GSM – 80 GSM

40D*75D • 40*100D • 40*150D

Double Dot Coating

Polyamide & Polyester & Blends

6 GSM – 35 GSM

Wenfuse®

Extrusion Webs and Films

Belt Loop Fusibles – Anti Fray 60”

Pre-Slit ½” – 3” 2 – 6 Mil Thickness

10 Grams – 80 Grams

EVA – PVC – PA – PES – PU – PVA

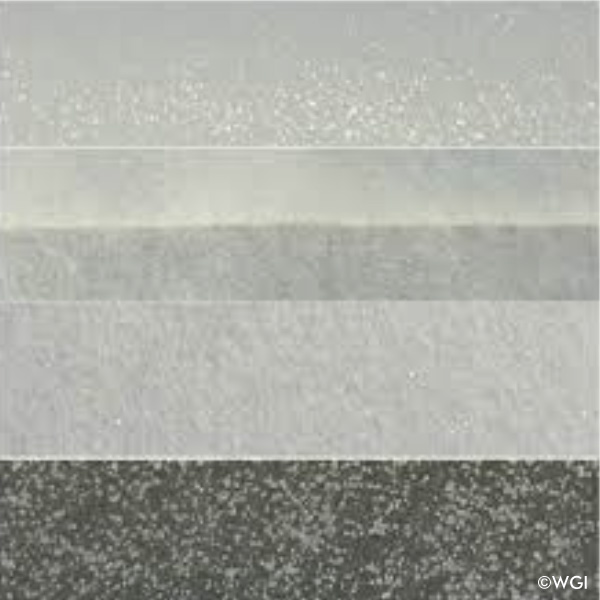

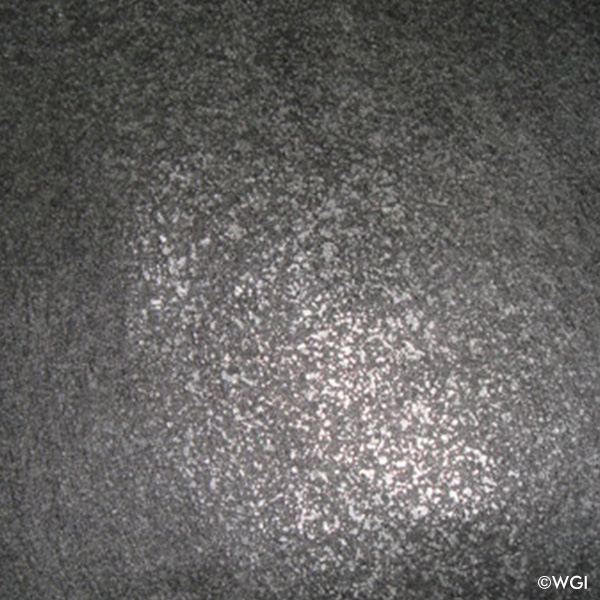

Coating

Polyamide & Polyester & Blends

GERMANY AND SWISS TECHNOLOGY

DOT FORMATIONS – Over 50 Variations

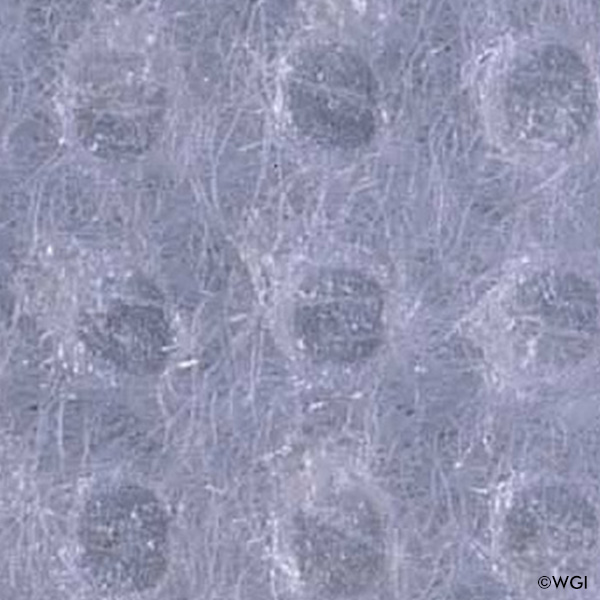

STRAIGHT LINE 15 – 80 MESH AND COMPUTER FORMATIONS – CP20 – CP99

COATING WEIGHTS FROM 6 GSM – 50 GSM

3,000,000 MONTHLY CAPACITY

Widths up to 300 CM/120”

Enzyme Wash Coatings

Low Melt and High Melt Temperature Ranges

High Bond Strength Integrity

High and Low Viscosity Flows

Double Sided Coated

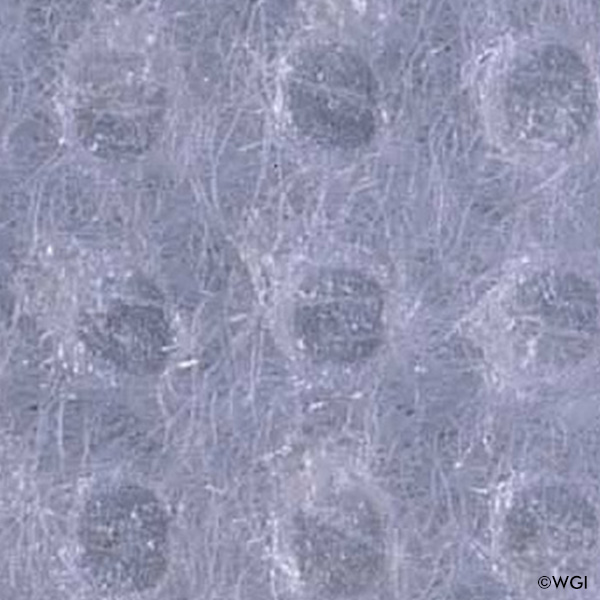

Micro-Dot Technology

Soft Hand Results

Swiss & German Technology

High Density Polyethylene Resin Systems

3 Grams to 50 Grams Coating

Strong Bond Strength

Firm and Softer Hands

Controlled Shrinkage

Swiss & German Technology

High Performance Washing and Dry-Cleaning

10 • 12 • 14 • 16 • 18 • 20 • 25 • 28 • 30 Mesh Dot

Highly Consistent Coverage

Superior Wash and Dry Clean Results

Low Shrinkage Rates < 2%

Excellent After Fusing Presentations

Micro-Dot Patterns for no Dot show-through

Quality Control

CONTINUES IMPROVEMENT PLANNING

IN LINE INSPECTION AND SECONDARY INSPECTION PROCESS

THIRD PARTY AUDIT COMPLIANCE

Quality Performance Standards & Testing

Wash Testing & Abrasion Testing — ASTM-D3511 & Bond Testing — ASTM-2724

Wash & Dry Clean Verification

Strength of Tear and Separation Analysis

Fabric & Interlining Compatibility Demographics

Standard Variation Interfacing Acceptability Models

Flame Retardant Testing — NFPA-701 & ASTM-D6413

INSPECTION

Process Control Audits – Internal and 3rd Party

Visual & IR Light and Computer Image Inspections

Harmful Substances Monitoring

Defect Analysis & Extraction Surveillance

Standards Compliance Monitoring

Computerized In-line Quality Management Programs

Weight Testing — ASTM-D3776M & Thickness Testing — ASTM-D1777

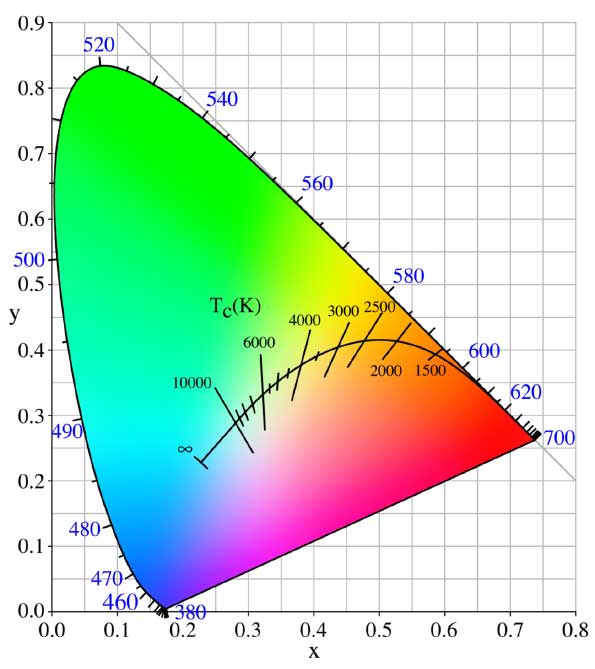

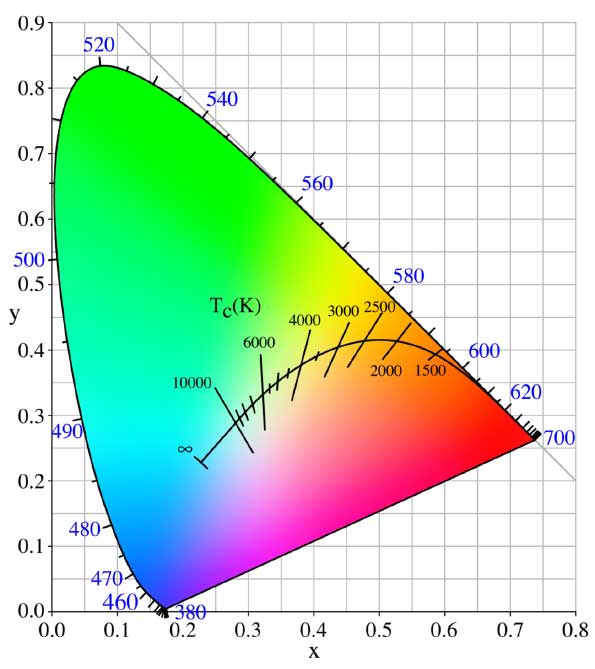

Color & White Shade Testing

Global Logistics

Over 15,000,000 yards of interlining stock worldwide

Asia, North America, South American, Europe, and Africa

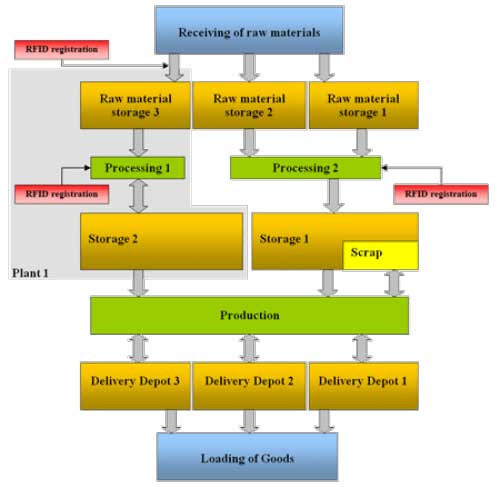

Efficient loading systems

Directly at Taizhou Port – Nanjing Port

Next to our factory and also loading directly to Port of Shanghai

By sea, rail, and trucks within China

2,000,000 pounds monthly of capacity in our integrated production systems

Stock maintenance programs

Think Globally – Act Locally

Value Added – Customer Driven

Synergistic Seamless Global Solutions

or Door to Door service to:

Vietnam

Indonesia

Bangladesh

Thailand

South Korea

Japan

Environmentally Sustainable

OUR POLICY

- Integrate the consideration of environmental concerns and impacts into our decision making and activities.

- Minimize our waste and then reuse or recycle fibers and chemicals as much as possible.

- Minimize energy and water use within our buildings and processes in order to conserve supplies and minimise the consumption of natural resources.

- As is possible, purchase products and services that do the least damage to the environment.

- Train, educate, and inform our employees about environmental issues that may affect their work.

- Promote environmental awareness among our employees and encourage them to work in an environmentally responsible manner.

- Communicate our environmental commitment to clients, customers, and the public and encourage them to support it.