Quality Control

CONTINUES IMPROVEMENT PLANNING

IN LINE INSPECTION AND SECONDARY INSPECTION PROCESS

THIRD PARTY AUDIT COMPLIANCE

Quality Performance Standards & Testing

Wash Testing & Abrasion Testing — ASTM-D3511 & Bond Testing — ASTM-2724

Pilling and Brush Resistance – Surface Changes

Wash & Dry Clean Verification

Strength of Tear and Separation Analysis

Fabric & Interlining Compatibility Demographics

Standard Variation Interfacing Acceptability Models

Flame Retardant Testing — NFPA-701 & ASTM-D6413

INSPECTION

Process Control Audits – Internal and 3rd Party

Visual & IR Light and Computer Image Inspections

Harmful Substances Monitoring

Defect Analysis & Extraction Surveillance

Standards Compliance Monitoring

Computerized In-line Quality Management Programs

Weight Testing — ASTM-D3776M & Thickness Testing — ASTM-D1777

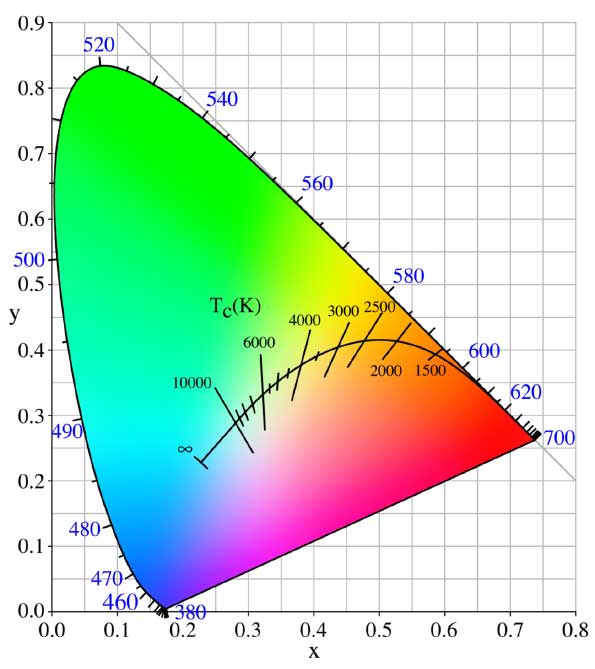

Color & White Shade Testing

OEKO-TEX- CERTIFICATION

We believe, developing environmentally sustainable business practices is a vital step toward decreasing our company’s carbon footprint, increasing its competitive advantage, and preparing our planet for future generations.

OUR POLICY

- Integrate the consideration of environmental concerns and impacts into our decision making and activities.

- Minimize our waste and then reuse or recycle fibers and chemicals as much as possible.

- Minimize energy and water use within our buildings and processes in order to conserve supplies and minimise the consumption of natural resources.

- As is possible, purchase products and services that do the least damage to the environment.

- Train, educate, and inform our employees about environmental issues that may affect their work.

- Promote environmental awareness among our employees and encourage them to work in an environmentally responsible manner.

- Communicate our environmental commitment to clients, customers, and the public and encourage them to support it.